X-HYF

EXRAIL X35 X45 X55

New generation needle roller guide that combines high rigidity, high motion accuracy and high damping performance.

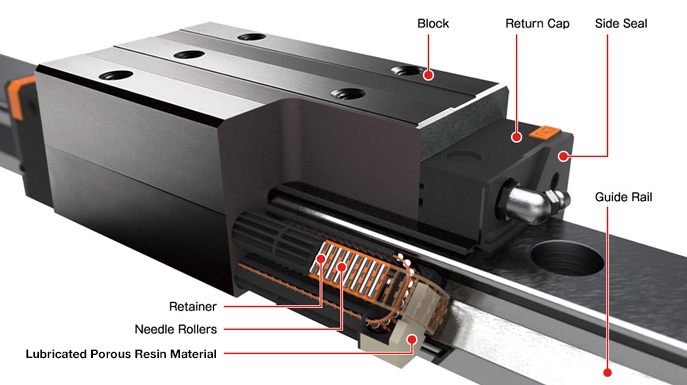

Structure

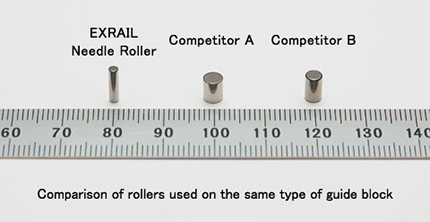

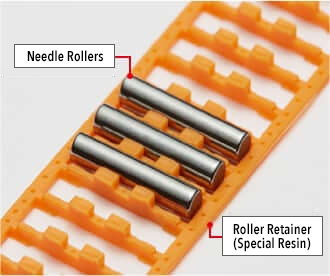

Adoption of needle roller

The use of needle rollers for the rolling elements enables a significant increase in the number of effective rollers and a wider contact surface of the rollers, resulting in high rigidity, high motion accuracy, and high damping performance.

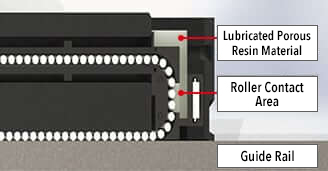

Long-term maintenance free

Lubricated porous resin material is in contact with the rollers, contributing to longer maintenance intervals.

Retainer mounted

The retainer restrains skew and eliminates roller jamming, resulting in smooth circulation.

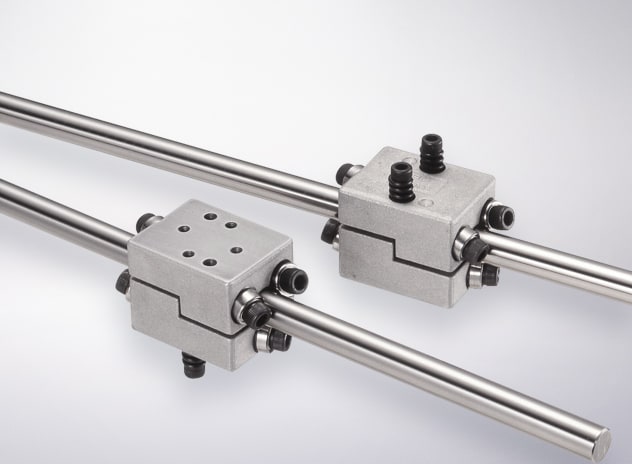

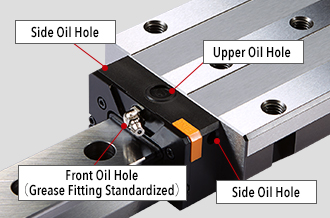

Supporting multi-directional relubrication

Flexibility in lubrication operations has been improved by placing lubrication holes in each of the three directions (front, top, and side).

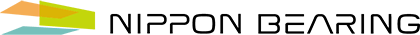

The brand badge is the proof of quality

The orange brand badge that first catches your eye when you pick up EXRAIL is a the proof that promises quality as a component that determines the value of the final product.

Features

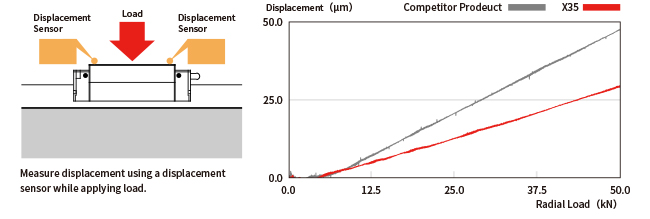

High rigidity

The amount of elastic deformation of each roller is reduced to realize 1.5 times or more the rigidity of conventional products. By using a large number of needle rollers that are longer and smaller in diameter than normal rollers, the load on each roller is reduced and rigidity is increased by more than 1.5 times.

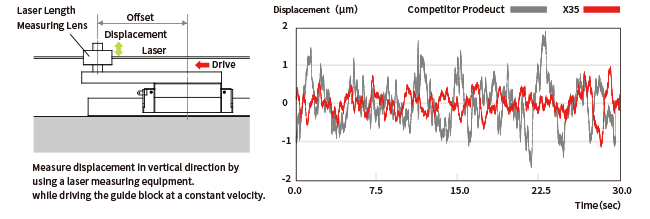

High motion accuracy

Loads are applied by a large number of small-diameter rollers, reducing vibration* of passing rolling elements to less than half of the conventional level.

By using a large number of small-diameter needle rollers to support the load, the vibration* that occurs when the guide is driven is reduced to less than 1/2.

*Periodic posture changes of the block due to changes in the position and total number of rolling elements supporting the load.

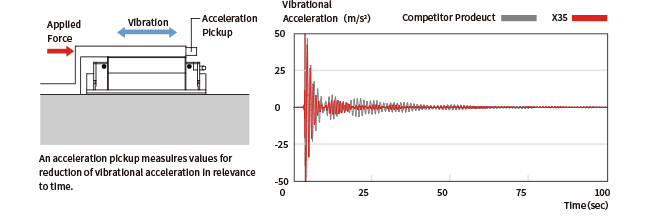

High damping capability

Vibration damping capability is improved more than 1.5 times higher than conventional products due to the friction of a large number of rollers.

The increased number of rollers results in a relatively large dynamic frictional force, which quickly settles vibrations and achieves a high damping capability more than 1.5 times greater than that of conventional products.